Your strategic partner in plastics

innovation – since 1965

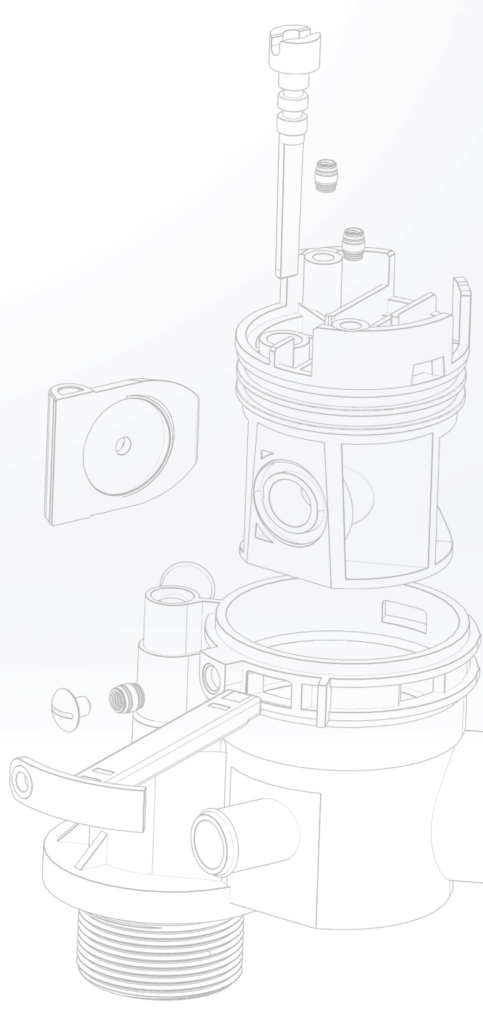

We are ready to help design and build your most complex injection molded parts. From ideation and engineering design review to tool build, project completion, and ongoing production support, you can trust CPI to deliver reliable technical injection molding solutions.

WHO WE ARE

Custom Plastics International (CPI) is not your

typical commodity plastics manufacturer; we are your strategic partner in plastics innovation. We help design, engineer, build and manufacture complex injection molded parts – leveraging over 60 years of expertise to drive innovation.

We leverage our advanced engineering expertise and high level of quality control to deliver impactful technical solutions that drive customer success through flexible, responsive collaboration. Customers value our stability, decades of industry experience, highly skilled team, and our industry-leading processes. We invest in cutting-edge technology, state-of-the-art equipment, and skilled staff to deliver strategic manufacturing solutions.

OUR HISTORY

Founded in 1965 in Cobourg, Ontario, Canada, Custom Plastics continues to utilize our hands-on management style and technical expertise to build a loyal customer base that supports our sustainable company growth today and into the future.

Company highlights

Injection Molding Equipment

35-500

Clamp

Tonnage

Tool Design & commissioning

Solid local and

offshore partners

IN-HOUSE

TOOL ROOM

BUILD AND REPAIR TOOLING

ON-SITE

ISO 9001:2015 AND

CGP REGISTERED

QUALITY PARTS YOU CAN TRUST

INDUSTRY-LEADING

ENTERPRISE RESOURCE

PLANNING (ERP) SYSTEM

WITH REAL TIME MONITORING

HIGHLY SOPHISTICATED

PROJECT MANAGEMENT TOOLS

For On Time Delivery and Project Success

continual investment

in r&d and equipment

21

Automated Injection Molding machines

SCALABLE OPERATIONS

40,000

sq. ft

(WITH ROOM TO GROW

on

8 acres of land)

SUSTAINABLE GROWTH

+70

EMPLOYEES

Strategic management with environmental awareness

Our Expertise

Whether your products have simple or complex geometries, our injection molding capabilities allow us to consistently produce durable, precision, thermoplastic products. Our advanced molding approach and internal processes ensure unwavering quality and reliability across all production runs.

From initial concept to final validation, we offer comprehensive tool design and commissioning services. Our team uses detailed checklists and industry standards to optimize tooling for longevity, accuracy, and efficiency.

From the addition of a single threaded insert to multi-level assemblies & post-mold decoration/finishing processes, CPI has decades of experience adding value to plastic parts. We do not shy away from a challenge; our advanced assembly techniques and automation ensure efficient, high-quality finishing on every project.

Since 1965, CPI has been dedicated to supporting our customers through every phase of the production process, from early design consultation to full program management. Our collaborative approach ensures we exceed customer requirements with precision and diligence every time.

Our LEADERSHIP TEAM

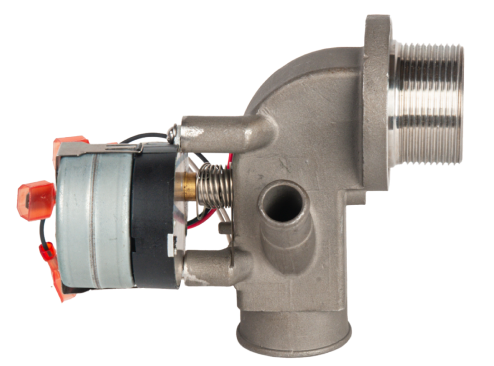

By cultivating a team of passionate, driven individuals and providing them with the tools and opportunities to thrive, we ensure that CPI remains a leader in the injection molding industry.

JIM

MAJURY

VP, GENERAL MANAGER

Jim Majury holds a B.A.Sc. in Mechanical Engineering (P.Eng.) from the University of Waterloo and brings 35+ years of experience in plastics manufacturing. As Vice President & General Manager, he provides strategic leadership across operations, finance and IT, supply chain, quality, engineering, and HR, ensuring alignment with the company’s long-term growth objectives.

With strong financial and operational acumen, Jim drives profitability, efficiency, and regulatory compliance while fostering a culture of innovation, accountability, and continual improvement.

His expertise in quality management systems, health and safety certification, and process optimization enhances performance across all areas of the business. A skilled negotiator and problem-solver, Jim’s collaborative leadership approach empowers teams to navigate complex challenges and deliver high-quality, reliable solutions that drive long-term customer success.

KELSON

LACHANCE

VP, ENGINEERING MANAGER

With over 30 years of experience in plastics engineering and a B.E.Sc. in Mechanical Engineering from the University of Western Ontario, Kelson Lachance, P.Eng., drives innovation in tooling, automation, and scientific injection molding at Custom Plastics International. He specializes in optimizing processes for precision, efficiency, and reliability, helping customers turn concepts into scalable, manufacturable products.

Kelson leads a highly skilled engineering team, ensuring that every project is supported by cutting-edge technology and best-in-class manufacturing practices. He works closely with customers to bridge the gap between ideation and production, delivering high-quality, cost-effective solutions that support long-term success.

LEE

CATTELL

VP, SALES

With over 30 years of experience in engineering sales and manufacturing within the plastics industry, Lee Cattell specializes in cost-effective solutions, thermoplastic selection, and process optimization. A Fleming College graduate, he began his career in advanced assembly, motion and time studies, and process improvement, before transitioning to sales in 2000.

Lee applies Kaizen methodologies and cost-reduction strategies to help customers maximize efficiency and performance. He combines his technical expertise and customer-focused approach to guide clients through material selection, design optimization, and manufacturing efficiencies, ensuring tailored injection molding solutions.

Committed to building long-term, strategic relationships based on trust, transparency, and collaboration, Lee plays a key role in helping CPI deliver high-quality, scalable solutions that drive customer success.

Cultivating Innovation

Custom Plastics International (CPI) is not your typical commodity plastics manufacturer; we are your strategic partner in plastics innovation, ready to help design and build your most complex injection molded parts.

HIRE FOR INNOVATION

We intentionally seek out individuals who are passionate, curious, and naturally inclined to solve problems through design and discovery. From the moment a new employee joins CPI, they are part of an environment that celebrates and nurtures their unique talents. Our team is made up of individuals who love what they do, and this passion fuels their ability to innovate.

CULTURE OF GROWTH AND DISCOVERY

At CPI, we believe that innovation thrives when people are empowered to follow their interests. Employees are encouraged to explore new ideas, challenge the status quo, and pursue their passions. This freedom to innovate, coupled with a structured training plan, creates an environment where personal growth is just as important as technical development.

STRUCTURED YET FLEXIBLE TRAINING

While we provide structured training plans to ensure continuous skill development, we also support non-linear learning paths. Employees can choose to focus on specific areas of interest, diving deeper into topics that excite them, whether it’s advanced materials, new manufacturing processes, or cutting-edge design tools. This flexibility enables CPI to develop well-rounded innovators who contribute to both current and future projects.

CHALLENGE AND EMPOWER EMPLOYEES

CPI empowers its team members by giving them the autonomy to explore and take ownership of projects. Our team is not just tasked with routine work – they are given challenges that require creativity and innovative thinking. By fostering an atmosphere where employees are encouraged to experiment and build on their ideas, we ensure that every individual contributes to CPI’s culture of innovation.

INNOVATION THROUGH COLLABORATION

In addition to individual growth, CPI promotes cross-disciplinary collaboration. Whether it’s through team-based projects, collaborative design reviews, or shared problem-solving sessions, employees are constantly learning from each other, which further fuels innovation. This collaboration extends to our relationships with customers, where CPI acts as a partner in collaborative design optimization to deliver solutions that go beyond the ordinary.

We are always looking for top talent to join our growing team.

With no current openings, we welcome resumes for future consideration.

Contact us with your resume.