delivering innovative solutions in plastics manufacturing

Our Innovative Solutions

Our Innovative Solutions

Next Level Injection Molding

Advanced techniques and equipment used to provide precision and innovation

Advanced Engineering

Emphasis on design reviews, prototyping, and solving complex mold challenges.

In-House Tool Shop

Describes the in-house capabilities to design and maintain molds, ensuring quality and efficiency.

Materials

Highlights expertise in material selection and specifying the variety of resins used.

Automation & Robotics

Discusses the integration of robots and cobots for precision and operational efficiency.

Assembly & Finishings

Provides value-added services like CNC machining, pad printing, and custom packaging.

Quality Processes

Focuses on the adherence to ISO 9001 and quality management standards integrated into ERP.

Next-level

injection molding

Our leadership in the injection molding industry is built on leveraging cutting-edge technology to deliver precision, efficiency, and innovation in every project. We use the latest electric injection machines, equipment, and advanced software to consistently achieve industry-leading results. This includes employing scientific molding principles to create robust processes, ensuring that our customers receive consistent quality and reliability in every part.

Established Testing Processes

Utilizing comprehensive, documented, detailed Mold Test processes to ensure consistency and quality in production.

Scientific Decoupled Molding

By applying scientific molding principles we are producing robust processes, reducing variability, and ensuring long-term production success. We invest in ongoing training (via A. Routsis Associates) to ensure our team remains proficient in the latest scientific molding techniques.

Advanced Equipment

Our facility is equipped with both Arburg and Engel electric injection molding machines, supported by advanced robotics and cobots to maximize efficiency and precision.

Specialized Molding Techniques

We have expertise in Overmolding, Insert Molding, and In-Mold Decorating (IMD), along with many other specialized techniques to meet diverse product requirements.

Continuous Improvement and Training

Regular training programs ensure our workforce stays skilled in the latest injection molding techniques.

ADVANCED

Engineering

We focus on delivering advanced engineering solutions through Engineering Design Reviews (EDR), rapid prototyping, plastic part design, and tool development. Our approach leverages cutting-edge tools and automation to streamline complex production processes and ensure high-quality results.

Collaborative Design Optimization

We integrate all aspects of product development—mold design, part design, assembly, and manufacturing—to optimize for manufacturability, performance, and cost-efficiency.

Engineering Design Review (EDR)

Our detailed checklists and standardized processes ensure thorough evaluation at every stage, including preliminary tooling concepts, part drawings, metrology, FMEA, and PPAP requirements.

Design & Analysis Capabilities

We utilize advanced tools (SolidWorks CAD, 3D Printing, CNC, FEA, Moldflow Simulation, GD&T, and metrology inspection) to develop products, solve complex challenges, and help commercialize concepts.

Project Management

We manage multiple complex projects in parallel, closely monitoring timelines to ensure deadlines are met and lead times maintained.

Automation Specialists

Onsite specialists enhance production efficiency by integrating automation, resulting in improved product quality, consistency, and operational efficiency.

Software Utilized

We utilize the latest versions of SolidWorks (with Simulation Premium), CAMWorks, Moldflow Mold Advisor, and PolyWorks to facilitate efficient design and development.

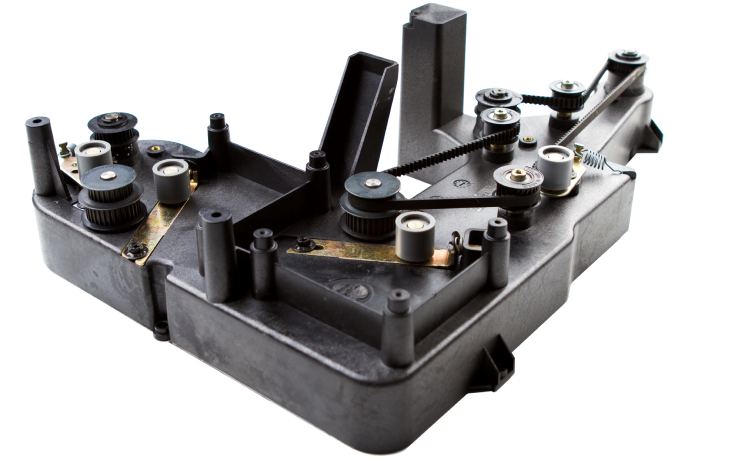

In-house tool shop

Our in-house tool shop is integral to our operations, providing expert mold-making and mold maintenance services. We maintain mold quality through a structured ERP-driven maintenance program, with automatic work order scheduling based on usage data to ensure mold quality and reduce downtime.

Our experienced team benefits from an in-house development program, ensuring continuous skill improvement.

Preventative Maintenance Program – individual maintenance plans are established through the ERP system. Molds are automatically scheduled for maintenance based on actual usage. The system automatically tracks and documents maintenance activities.

We adhere to strict North American mold standards (SPI Class guidelines, etc.) to ensure every tool meets industry specifications for safety and quality.

We maintain molds throughout the life of the program to ensure quality parts and efficient operation.

Our team designs, builds, and maintains high-quality injection molds. We also have close relationships with local schools to develop the next generation of skilled mold makers through apprenticeships and in-house training programs.

Materials

Specialized Equipment

Our facility is equipped with advanced injection machines, high-heat thermolators, dryers, moisture analyzers, and grinders necessary for processing engineering materials effectively.

Engineering Experience in Material Selection

Extensive expertise in selecting and understanding material properties. Our engineering team is proficient in designing parts, molds, and molding parameters to ensure success with highly engineered materials.

Materials We Use

ABS

PC/ABS

PPA

ACETAL (POM)

PEEK

PPO

ACRYLIC (PMMA)

PET

PPS

HDPE

PI

PPSU (POLYPHENYLSULFONE)

LCP

POLYCARBONATE

PSU

POLYPROPYLENE

TPE/TPU/TPV

PBT

POLYSTYRENE

We also have vast experience with filled and reinforced resins (flame-retardant additives, glass or carbon fiber reinforcement, PTFE/Teflon, EMI shielding additives, talc fillers, etc.).

AUTOMATION &

Robotics

We have developed our own proprietary modular system for cobot integration, providing high flexibility and rapid deployment for various production needs. Our system enables quick setup of jobs using various secondary modules, such as packing, adhesive dispensing, and machine tending. This modular approach ensures that automation can be efficiently integrated into existing workflows, enhancing productivity and reducing cycle times.

Advanced Data Analysis and

AI Integration

Leveraging AI and ERP interfaces to track reject rates and attribute levels, enhancing quality control and process optimization. Every shot is accounted for and tracked.

In-House Fixture Builds

Design and development of all required fixtures, including EOAT (End of Arm Tooling) and component parts. All fixtures are designed and fabricated in-house using our CNC machines and multiple 3D printers, ensuring custom solutions for automation needs.

Flexible Automation Modules

Our modular stations include adhesive dispensing, bagging, machine tending, packaging, and vision for pick and place operations.

Modular Automation System

Our modular automation system allows quick reconfiguration and setup of automation cells to adapt to different products or tasks.

Integration of Robots

and Cobots

Industrial robots and cobots are used throughout production to maximize efficiency.

Assembly & Finishings

Our assembly and finishings department complements our molding capabilities by providing services ranging from simple to complex assemblies. Our team has the tools and experience necessary to ensure that products meet our rigorous standards of quality.

In-House Design for Assembly

Early in the process, our Engineering experts help customers with design for assembly (DFA), reducing costs and improving quality.

High Speed CNC Machining and Tapping

We machine complex geometries to achieve tolerances not possible with direct injection molding.

Assembly Services

We offer assembly, pad printing, cobot adhesive dispensing, ultrasonic welding, Heat staking, custom kitting/bagging, CNC machining, tapping, painting, plating and EMI coatings.

Bill of Materials (BOM) Management

We leverage our ERP system to manage comprehensive parts lists, control inventory levels, and maintain on-time delivery schedules.

VALUE ADDED SERVICES

- In-house design & prototyping

- Simple to complex assembly

- Metal replacement

- Insert molding, over-molding

- In-mold decorating (IMD)

- Automation

- ISO7 mobile cleanroom

- Pad printing

- Silk screening

- Painting

- Heat-staking

- CNC machining

- Hard coating

- Ultrasonic welding

- EMI shielding

- Plating (dip and selective)

- Robot controlled adhesive bonding

- Vacuum metallizing

- Kit and customer end use packaging

Quality ProcessES

& Metrology

Quality is the backbone of our operations at Custom Plastics International Ltd. We adhere to stringent quality standards and certifications, ensuring that our products and processes consistently meet and exceed customer expectations. Our comprehensive Quality Management System (QMS), integrated with our ERP2 system, provides a seamless and efficient approach to quality management across all aspects of our business. CPI is fully equipped to handle all your measurement needs, using the latest inspection tools for precise and efficient results.

Certifications

ISO 9001:2015 certified for quality management, and Controlled Goods Program (CGP) registration for compliance with security regulations.

Process-Centric Quality Management

Our QMS is fully integrated into every aspect of our operations through the ERP2 system, specifically designed for the injection molding industry. This ensures seamless quality control and consistent quality at every step of the production process.

Metrology and Quality Control

We employ advanced metrology in our quality control. For example, we generate thorough First Article Inspection (FAI) and PPAP reports, perform capability studies and Gage R&R studies, and use Statistical Process Control (SPC) to ensure long-term consistency.

Customer focus

We provide dedicated customer support and maintain integrated traceability systems to ensure full visibility throughout the production process.

Inspection tools

We utilize Coordinate Measuring Machines (CMM), precision optical measuring equipment, Computed Tomography (CT), and laser scanners for high-precision verification.

let’s collaborate on

your next plastics project