Ready to help design and build your most complex injection molded parts

Custom solutions start with

innovative problem-solving

We draw on knowledge from thousands of successful projects. Using that vast experience, we develop highly customized solutions that ensure our customers’ success.

3

pillars of innovation

3

pillars of innovation

We innovate by combining our scientific research, technological leadership, and quality management to deliver industry leading technical molding solutions.

1

Scientific Research and Development

Engineering innovation is a tangible outcome of our rigorous Research and Development programs. We drive innovation in injection molding by using these programs to solve complex challenges in material performance, mold design and automation.

1

Scientific Research and Development

Engineering innovation is a tangible outcome of our rigorous Research and Development programs. We drive innovation in injection molding by using these programs to solve complex challenges in material performance, mold design and automation.

Automation for Complex Manufacturing

Our modular cobot integration streamlines secondary operations, including loading, packing, bagging, dispensing, and assembly. The cobots feature adaptive positioning, allowing for precise setup and seamless flexibility across various secondary operations or modules. This adaptability enhances their integration into existing workflows, improving repeatability, reducing cycle times, and minimizing downtime. Their flexible design ensures efficient performance across multiple processes, maintaining consistent accuracy and operational efficiency.

Innovative

Mold Design

We use advanced simulations and testing to optimize gating, runner systems, and cooling strategies, which enhance part design, reduce defects, and create a robust molding process. By continually refining our methods, we address common challenges like weld lines and sink marks, resulting in a consistently reliable and robust molding process.

Material science & process optimization

We utilize a systematic approach and scientific decoupled molding principles to master the processing of highly engineered materials. By separating and analyzing critical stages of the molding process, we refine tooling designs and optimize molding parameters to achieve precise tolerances. Our detailed mold testing procedures ensure reliable flow and eliminate defects, even in the most complex geometries. This approach enables us to handle the most challenging engineering polymers, such as PEEK, PEKK, PPS, PSU, and PEI, with confidence and accuracy.

Future Technologies

Our research into vision and sensor technology, combined with AI-based controls, drives our advancements in automation. Vision systems play a critical role in our modular cobot automation, handling inspection, part identification, part measurement, and guidance for accurate handling. These integrated technologies enhance our cobots’ flexibility and efficiency, allowing them to seamlessly adapt to multiple tasks across various workstations, boosting overall productivity and precision.

2

Technological Leadership

At CPI, we lead the industry by adopting cutting-edge technologies that solve complex customer challenges. Our vast experience across diverse projects enables us to recognize patterns and develop tailored solutions quickly and efficiently. This depth of knowledge allows us to inject precision, speed, and innovation into all our projects, pushing the boundaries of what’s possible in injection molding.

2

At CPI, we lead the industry by adopting cutting-edge technologies that solve complex customer challenges. Our vast experience across diverse projects enables us to recognize patterns and develop tailored solutions quickly and efficiently. This depth of knowledge allows us to inject precision, speed, and innovation into all our projects, pushing the boundaries of what’s possible in injection molding.

Advanced Machinery and Automation

CPI’s production floor features Arburg and Engel injection machines, most paired with 5-axis robots for precision, repeatability, and high-speed automated production. These systems ensure consistent quality, even for complex parts. Our modular approach, utilizing UR Cobots, adds flexibility by seamlessly performing tasks like overmolding, assembly, and material handling with precision.

High-Speed CNC and Precision Machining

Our high-speed CNC machines enable precision manufacturing, reducing lead times while maintaining exact tolerances. These can be machine-tended with Cobot integration.

Servo Heat Stake machines

We utilize servo-driven heat staking machines to provide precision in post-molding operations like assembly, staking, and bonding.

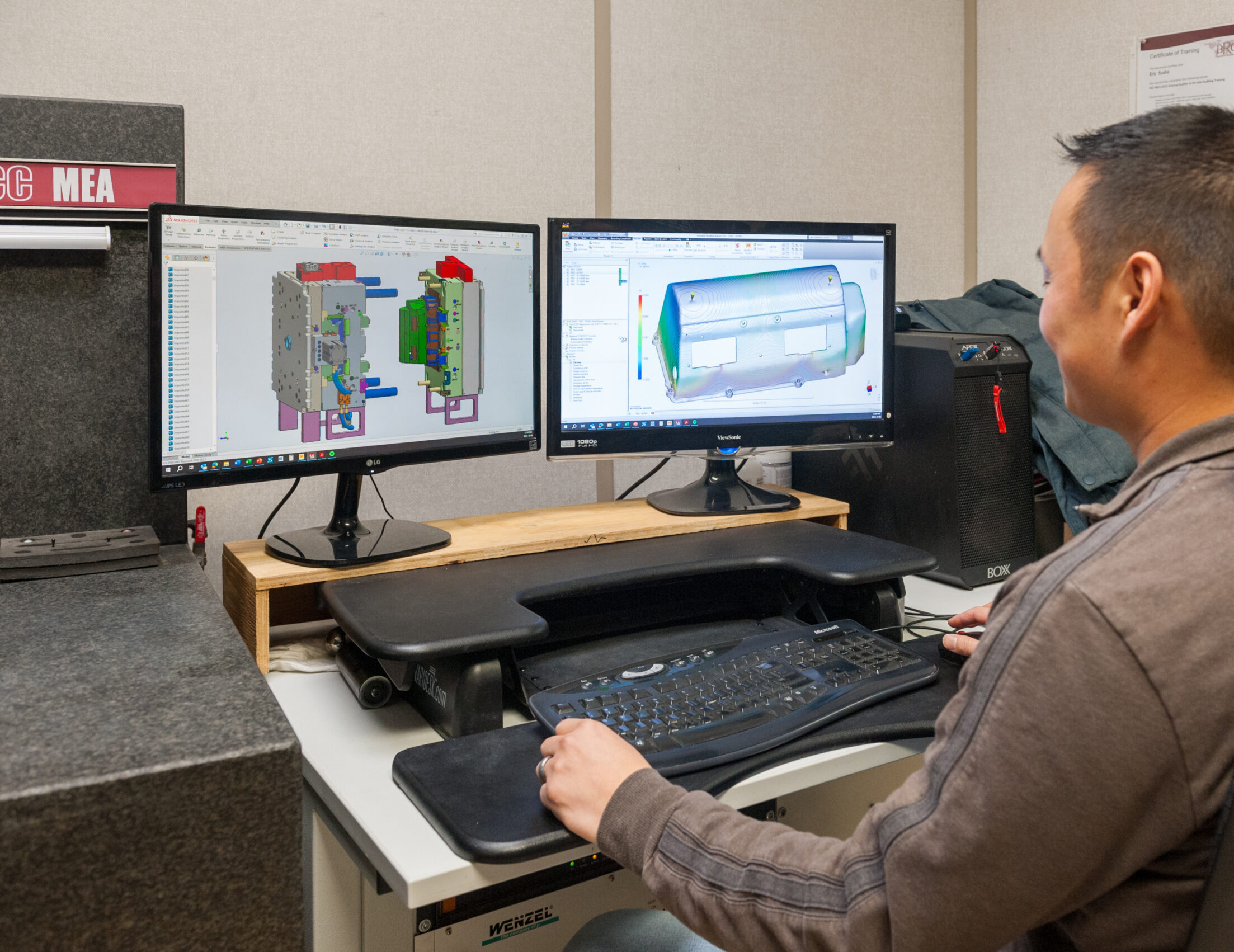

3D Printing of Rapid Prototypes

CPI utilizes a range of advanced 3D printers and CNC machining to quickly develop prototypes and tools for complex projects. These capabilities allow us to accelerate development timelines, ensuring both functional testing and precise validation before moving into full-scale production.

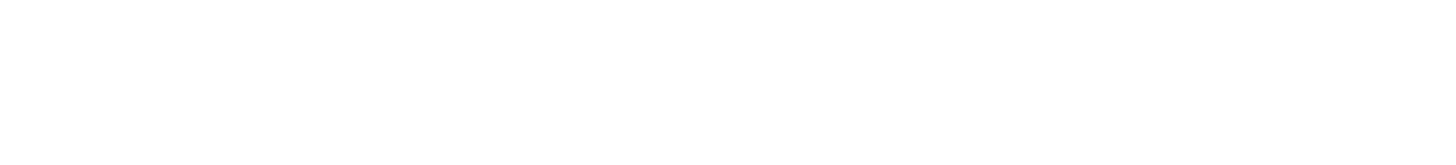

Metrology and Quality Assurance

CPI employs advanced metrology processes, including Coordinate Measuring Machines (CMM), Image Measurement Machines (IMM), Computed Tomography (CT) scanners, and ultra-precise laser scanners, for high-precision dimensional verification and validation. These technologies capture intricate details with exceptional accuracy, allowing us to verify parts against design specifications. The data gathered provides valuable statistical insights, ensuring long-term process stability and consistent quality.

Industry-Leading Software for Design and Analysis

SolidWorks and CAMWorks for product design and CNC programming.

Moldflow for simulating mold performance and optimizing process parameters.

SolidWorks Simulation Premium (Finite Element Analysis) for evaluating designs for nonlinear and dynamic response.

PolyWorks allows us to provide comprehensive inspections and analysis by integrating data from CMM, CT scanning, and laser scanners. This powerful software platform coordinates all of our inspection processes and statistical analysis, ensuring precise measurement and verification across multiple data sources.

3

Quality Management

Quality is at the core of how we manage and improve our business. Our entire operation is integrated into a proprietary Quality Management System (QMS), seamlessly woven into our DELMIAWorks ERP system. This ERP manages everything from quoting to invoicing, ensuring each process is tracked, analyzed, and optimized for quality, efficiency, and cost control. Adherence to ISO 9001:2015 means Quality parts you can trust.

3

Quality is at the core of how we manage and improve our business. Our entire operation is integrated into a proprietary Quality Management System (QMS), seamlessly woven into our DELMIAWorks ERP system. This ERP manages everything from quoting to invoicing, ensuring each process is tracked, analyzed, and optimized for quality, efficiency, and cost control. Adherence to ISO 9001:2015 means Quality parts you can trust.

Process-Centric

Approach

CPI follows a process-centric model, continuously refining and improving workflows. Our proprietary processes are rigorously tested and updated to ensure maximum efficiency and quality, with detailed checklists and forms in place to guarantee consistency and reliability at every step.

Integrated Systems for Total Control

All of our processes are fully integrated into the DELMIAWorks ERP system, providing real-time data across the production lifecycle. This system offers complete visibility and control, allowing us to track projects and address issues before they impact the final product.

Real-Time Monitoring

and Analysis

CPI’s processes are tracked in real-time, monitoring cycle times, scrap rates, and key metrics for each production run. Every shot and cycle is recorded, allowing us to review the data through the use of Power BI analytics before the next run and ensure consistent quality across all projects.

Gap Identification and Continuous Improvement

Our system identifies gaps or inefficiencies, and our team swiftly addresses them with solutions. Using real-time monitoring and historical data, we focus on reducing scrap, optimizing cycle times, and improving efficiency to drive continuous innovation.

Costing and Efficiency

CPI has a deep understanding of costs, accurately tracking the cost of every part and cycle. By integrating our ERP with real-time monitoring, we offer competitive pricing without sacrificing quality, ensuring our costing models reflect current operations.

HOW WE WORK

Our engineering process helps customers commercialize ideas through a structured, iterative approach. Each member of our team brings 15-30 years of experience, combining technical expertise with collaborative problem-solving. We integrate industry standards, detailed checklists, and thorough design reviews to ensure every project reaches its full potential.

Our Customer-Centric Engineering and Collaborative Design Optimization – Your Competitive Advantage

Collaborative Design Optimization

CPI’s Collaborative Design Optimization process considers all aspects of product development—mold design, part design, assembly, and manufacturing—together. Our team refines each element through multiple iterations to ensure the best solution. This systems-based approach optimizes designs for manufacturability, performance, and cost-efficiency.

Engineering Design Review (EDR)

Our structured Engineering Design Review ensures thorough analysis at every stage. We use detailed checklists and industry standards to verify all design aspects – part design, metrology, tooling, processing, and assembly. This attention to detail enables CPI to help customers commercialize their ideas with a focus on cost efficiency and reliability.

Collaboration and Iteration

Collaboration is central to CPI’s engineering approach. Using online platforms and real-time design reviews, we work closely with customers to align design decisions with technical and commercial goals. This process allows for rapid design iterations, speeding up development and reducing costs.

Metrology and Quality Control

Quality is embedded in our process, with metrology ensuring design accuracy. We use high-precision scanners and metrology tools to validate part geometry, addressing any deviations early to prevent costly redesigns.

Prototyping and Mold Design

Our in-house 3D printing enables rapid prototyping for early design validation. This approach ensures customers receive parts that are functional and optimized for efficient manufacturing.

Comprehensive Tooling Design

We take a design-for-tooling approach to optimize part models for manufacturability. By focusing on mold filling analysis, cooling strategies, and part ejection mechanisms, we ensure that designs translate into efficient and repeatable manufacturing processes.

Industrial Equipment

The industrial equipment market covers industrial controls, energy management, and automation systems, all of which require precise, reliable, and durable components. Products in this sector must meet stringent regulatory standards and consistently perform in high-demand environments, often under harsh conditions.

CPI offers this segment custom injection molding solutions that:

- Deliver deep expertise in navigating agency requirements such as UL, ROHS, REACH, and PFAS regulations to ensure compliance across every product.

- Provide material solutions tailored to industrial environments, including rugged, cold-weather, and high-performance plastics, along with EMI shielding options.

- Develop large assemblies and manage complex part counts, ensuring quality, efficiency, and inventory management in high-volume production runs.

- Leverage advanced assembly techniques, including robotic dispensing and automated processes, to ensure precision and reliability.

- Manage the entire program lifecycle, from design and prototyping to full-scale production, offering seamless program management that meets tight deadlines and guarantees product integrity.

- Provide custom kitting solutions, where multiple parts, SKUs, and instructions are consolidated into ready-to-ship kits. These kits are efficiently packaged and shipped directly to drop points, streamlining logistics and offering customers a turnkey packaging and distribution solution.

Health & Medical

The health and medical market encompasses medical devices, diagnostics, and surgical technologies, which require the highest standards of precision and safety. Products in this segment must comply with medical industry standards and perform reliably in life-critical applications. CPI offers this segment custom injection molding solutions that:

- Include the use of ISO 7 mobile cleanrooms, ensuring a controlled environment for the production of medical parts, minimizing the risk of contamination.

- Provide medical-grade materials that are engineered for biocompatibility and sterilization resistance, tailored for non-implantable medical devices.

- Use CT scanning, inspection, and statistical analysis to ensure part capability, providing customers with high-confidence, quality-assured components.

- Employ in-process laser inspection to maintain long-term process control, ensuring that each part consistently meets stringent medical standards.

- Specialize in highly complex medical devices such as diagnostic equipment, surgical tools, and patient care technologies, offering precision molding for tight tolerances.

- Manage the entire program lifecycle, from design and prototyping to full-scale production and validation, ensuring seamless integration with customer needs and full traceability for process integrity.

Security & Military

The security and military market requires high-performance components that meet the rigorous standards of defense, security, and surveillance applications. Products in this sector must endure extreme conditions, adhere to government regulations, and provide mission-critical reliability. CPI offers this segment custom injection molding solutions that:

- Deliver durable and rugged components that meet the stringent requirements of military-grade and security equipment.

- Provide materials with enhanced properties such as impact resistance, temperature tolerance, and EMI shielding, ensuring components function in harsh environments.

- Adhere to Controlled Goods Program (CGP) compliance, ensuring CPI can meet defense and security-related production standards.

- Include advanced inspection and quality control measures such as CT scanning, in-process inspection, and statistical analysis to guarantee part integrity and long-term performance.

- Leverage advanced assembly techniques, including robotic processes and multi-part assemblies, to ensure precision and efficiency.

- Offer full program management, from concept and design to production and final delivery, with the ability to meet specialized defense and security requirements.

Transportation

The transportation market focuses on intelligent transportation systems (ITS), clean energy vehicles (including hydrogen and electric vehicles), and HVAC systems for vehicles across various industries. Products in this sector must ensure reliability, efficiency, and sustainability, while meeting the demands of urban mobility, traffic management, and clean energy initiatives. CPI offers this segment custom injection molding solutions that:

- Deliver high-performance components for HVAC systems used in vehicles across various industries, as well as parts for intelligent transportation systems, such as automated tolling, traffic management, and connected vehicle infrastructure.

- Provide precision-molded parts for clean energy vehicles, including hydrogen fuel cell and electric vehicle components that meet the demands of sustainable transportation.

- Offer durable materials designed to withstand the harsh conditions of transportation environments, including vibration, temperature extremes, and long-term wear.

- Ensure compliance with industry standards for sustainability and environmental regulations, helping customers meet evolving requirements for eco-friendly solutions.

- Design and develop multi-part louvers and flow control components for ventilation systems, ensuring that transportation solutions maintain optimal airflow and temperature control.

- Provide comprehensive program management, from design and prototyping to full-scale production, ensuring seamless integration into transportation systems.

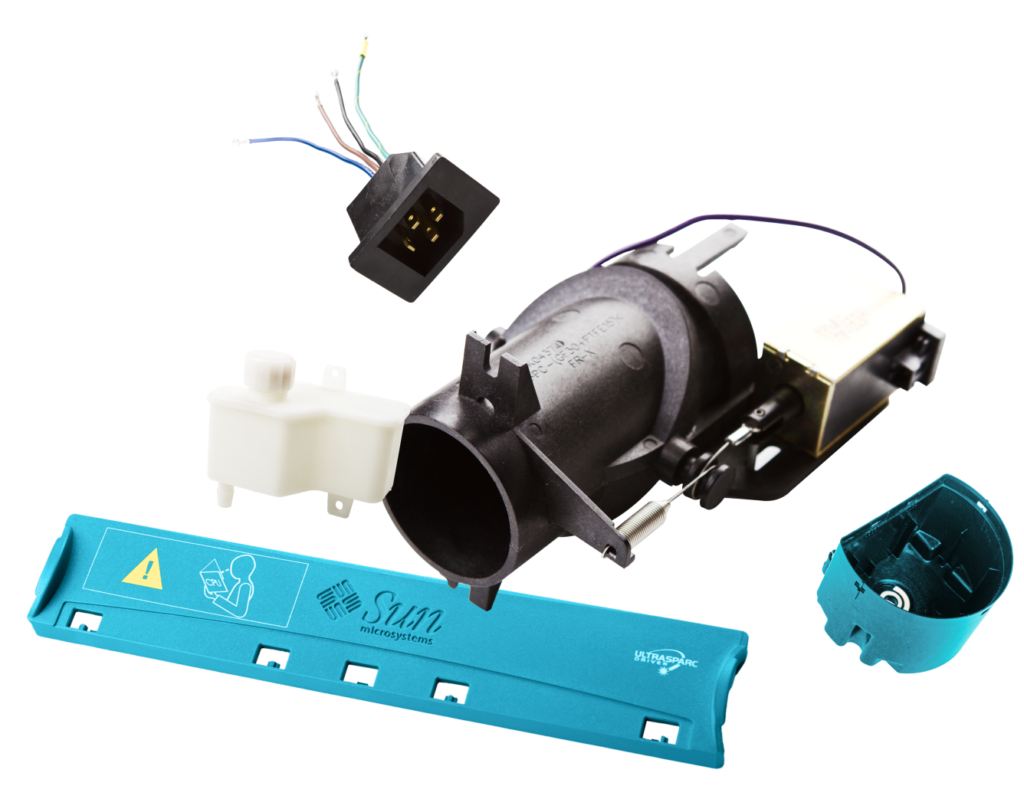

Business Equipment

The business equipment market encompasses technologies such as printers, copiers, scanners, and other office tools that require high-quality, durable, and repeatable components. This sector demands both cosmetic precision and functional reliability, alongside tight tolerances for high-volume production. CPI offers this segment custom injection molding solutions that:

- Provide high-quality, durable components for complex office equipment like printers, copiers, and scanners.

- Leverage our ERP system to ship to multiple customer locations, ensuring seamless logistics and timely deliveries for distributed operations.

- Offer specialized materials solutions, such as EMI shielding, lubricated materials, or static discharge properties, depending on the application’s specific needs.

- Design and develop highly cosmetic parts that meet the aesthetic standards required in customer-facing office products.

- Deliver expertise in high-part count assemblies and multi-SKU builds, managing large BOMs and complex inventory to ensure reliability and efficiency.

- Utilize advanced assembly techniques, such as robotic dispensing and automated assembly, to ensure precision and efficiency.

- Manage the entire program, from initial design and development to full-scale production, ensuring a seamless process from start to finish.

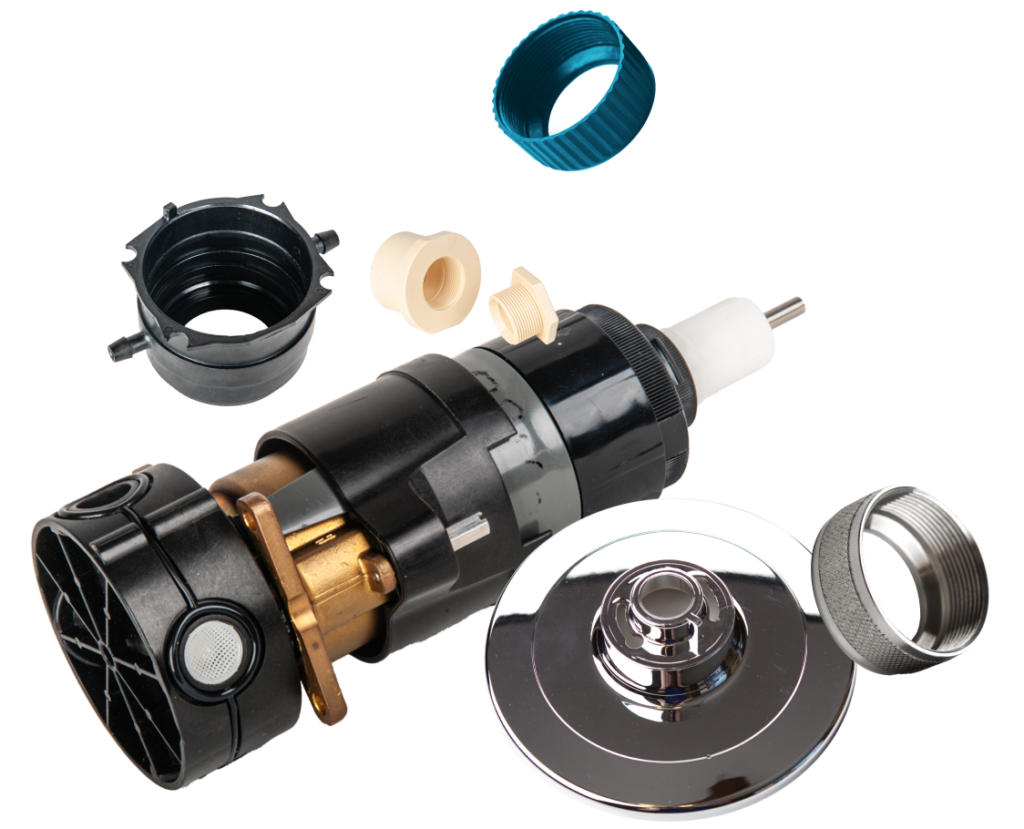

Water

The water industry focuses on providing clean water solutions, wastewater management, and industrial water treatment technologies, as well as solutions for residential pools and pool heaters. Products in this sector are essential for sustainability, water conservation, and ensuring access to safe drinking water in both residential and industrial applications. CPI offers this segment custom injection molding solutions that:

- Provide precision-engineered components for UV disinfection systems, advanced oxidation, and filtration technologies, ensuring the highest standards for municipal, industrial water treatment, and pool water filtration systems.

- Offer deep expertise in material selection, with a focus on understanding the effects of UV light on plastics, ensuring durability and performance for components exposed to UV disinfection processes.

- Deliver PVC and high-volume molding solutions for components used in pool filtration systems, well water systems, and pool heaters, providing cost-efficient and reliable solutions.

- Design and develop components for water flow control systems, such as valves and flow management devices, ensuring precision control of water processes across industries.

- Ensure compliance with environmental standards and support sustainability efforts by providing materials and products that reduce water waste and promote water conservation.

- Manage the entire program lifecycle, from design and prototyping to high-volume production, ensuring consistent, reliable, and scalable water treatment products.

Your Partner in Sustainability and Global Impact

While our plastics manufacturing process is inherently clean, enhanced by our use of recycled materials and optimized material efficiency, our greatest sustainability impact reaches far beyond our own operations. We play a key role in supporting projects and customers who are driving significant global advancements in sustainability and environmental protection.

Partnerships for Global Change

We work with companies that are addressing some of the world’s most pressing environmental challenges. For example, we partner with organizations in clean water technologies—helping design and manufacture components for systems that are cleaning wastewater, treating drinking water, and enabling water reuse. These systems are critical in regions facing water scarcity due to climate change, population growth, and aging infrastructure.

Carbon Capture and Environmental Solutions

CPI also supports direct carbon capture technologies, working with customers on innovative projects that aim to reduce greenhouse gases and combat climate change. By providing high-precision molded components for these projects, CPI is helping to advance technologies that play a significant role in global efforts to reduce carbon emissions.

Sustainable Material Choices

In addition to our global project involvement, we collaborate closely with our customers to choose environmentally friendly plastics and minimize material waste. By advising on the selection of sustainable materials and optimizing design for manufacturing, CPI reduces the environmental impact of each project we undertake.

Circular Manufacturing

Our commitment to sustainability is also evident in our manufacturing processes, where we minimize waste through recycling and regrind usage. Our real-time monitoring systems ensure that scrap and inefficiencies are continuously reduced, driving both economic and environmental benefits.

Through these partnerships and projects, CPI is making a tangible impact on global sustainability efforts, particularly in the areas of clean water, carbon capture, and sustainable materials. By supporting companies that are at the forefront of environmental innovation, we’re contributing to solutions that will have a lasting and meaningful impact on the world.

let’s collaborate on

your next plastics project